Patternation

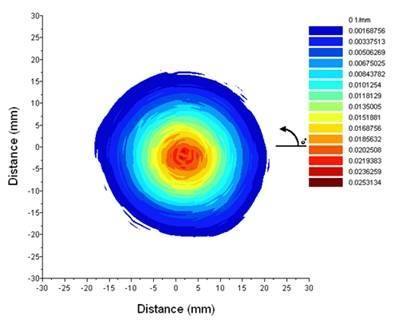

is the specialized technical art of performing quantitative measurements of

properties within a spray and then the patterns with the spray are visualized.

The process is used for nozzle testing. For smaller sprays, OP-200 patternator

is used and for bigger ones OP-660 is used. It is the common measurement that

is providing maximum output resulting in better resolution. The tests are done

in the laboratory and many types of nozzles & injectors are included in the

testing. Drop size refers to the size of the individual drops that comprises a

nozzle’s spray pattern USA.

Spray

patterns are providing a range of liquid drop sizes there are several factors

which affect the drop size. It includes liquid properties, nozzle capacity,

spray pressure and spray angle. The small drop size is produced for dust

suppression between 20 and 200 μm airborne dust particles are required of the

same range. A high degree of atomization is used for producing very small drop

size and that is achieved by pumping water through nozzles at high pressure.

Air atomization is the better choice if compressed air is available and

economically feasible.

Information obtained through spray patterns are –

- Patternator number

- Asymmetry ratio

- Local surface area of drops per unit volume

- Cone angle

- Presence of streaks and voids

Here is the detail of some of the characteristics –

Spray Angle: The range gets determined by the spray

patterns, the number of nozzles and the nozzle. It is ranging from 0° to 175°.

Operating Pressure: The moisture need defines the operating

pressure and flow rate. The nozzle operating should be placed close to the dust

source and it is best suited for enclosed areas.

Surface

Wetting: The nozzle is used to increase

the surface wetting and any impact can also increase surface wetting. The drops

are traveling through the turbulent air before they hit the material.

No comments:

Post a Comment